PRODUCTS

Contact Us

Address:

Building 4, Phase 2.5, Independent Entrepreneurship Park, Tianyi Science and Technology City, Tianyuan District, Zhuzhou City, Hunan Province, China

E-Mail:

chitanauto@163.com

Mr. Gong:

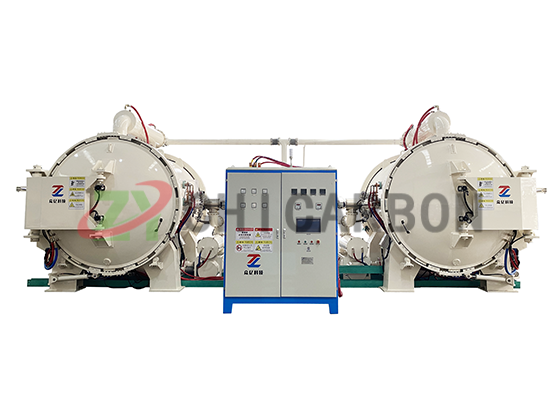

2200℃ Atmosphere Protected Sintering Furnace

keyword:

Atmosphere sintering furnace

Vacuum Atmosphere Sintering Furnace

Sintering furnace

2200℃ Atmosphere Protected Sintering Furnace

Product Description:

Applications: Atmosphere sintering furnaces are mainly used for vacuum and atmosphere sintering of silicon carbide, ceramics, cemented carbide, powder metallurgy, tungsten, molybdenum, AlNiCo permanent magnets, SmCO5, Sm2CO17, and alloys such as aluminum-iron-boron and titanium alloys.

Features:

- Products can achieve integrated dewaxing and sintering, greatly shortening the production cycle.

- High operating temperature: Maximum operating temperature is 2200℃.

- The equipment adopts a constant temperature field optimization design and multi-zone resistance heating with graphite rods (plates), resulting in a uniform temperature field within the furnace. It is an advanced high-temperature sintering equipment for pressureless and low-vacuum sintering.

- Equipped with a programmable controller and human-machine interface, it can be operated and monitored automatically throughout the process, with both fully automatic and manual modes.

- High safety, employing PLC automatic control and protection for water, electricity, and gas, with protection against over-temperature, water pressure, water flow, furnace over-pressure, and water temperature.

Technical Parameters and Model Specifications:

- Configuration: One-to-one or one-to-two

- Maximum Operating Temperature: 2200℃

- High-Temperature Zone Dimensions: L: 200-6000mm × W: 200-1500mm × H: 200-1500mm (or customized according to user requirements)

- Furnace Operating Environment: Vacuum, nitrogen, argon, hydrogen, etc.

- Temperature Uniformity: ≤±5-±15℃ (depending on the size of the high-temperature zone)

- Temperature Measurement Accuracy: 0.1%-0.5%

- Temperature Measurement Method: Low temperature: tungsten-rhenium thermocouple; High temperature: infrared thermometer.

- Control Method: PID segmented program control and manual control.

Product Specifications:

| Product Model Specification | ZY-TZL-400 | ZY--TZL-600 | ZY-TZL-800 | ZY-TZL-1050 | ZY-TZL-1500 |

| Size and Volume | 400×400×800 128L | 600×600×1800 648L | 800×800×2000 1280L | 1050×1050×2900 3200L | 1500×1500×6000 13500L |

| Rated Temperature (°C) | 2200 | 2200 | 2200 | 2200 | 2200 |

| Limiting Temperature (°C) | 2400 | 2400 | 2400 | 2400 | 2300 |

| Configuration Power (KW) | 150 | 350 | 450 | 800 | 2000 |

| Temperature Difference in high Temperature Zone (℃) | ±5 | ±5 | ±10 | ±15 | ±15 |

| Temperature Control Method | PID segmented programme control and manual control | ||||

| Heating Method | Graphite, tungsten, molybdenum, etc. resistance heating | ||||

| Operating Atmosphere | Vacuum, nitrogen, argon, hydrogen | ||||

| Ultimate Vacuum (pa) | 0.0067 (empty furnace, cool state) (or customised according to customer requirements) | ||||

Product Showcase:

RELATED PRODUCTS

2800℃ One-to-Two Graphitization Furnace

The One-to-Two Graphitization Furnace is a high-temperature graphitization furnace mainly used for the graphitization of graphene oxide, PI thermal conductive films, sintering and graphitization of carbon fiber ropes and filaments, sintering and graphitization of carbon materials, graphitization of anode materials, and other carbon materials, carbon-carbon and carbon-ceramic composite materials, as well as high-temperature sintering and graphitization of industrial ceramics and powder metallurgy materials.

ONLINE CONSULTATION

Filling in your phone and email information will help us get in touch with you in a timely manner and resolve your issue as soon as possible.