PRODUCTS

Contact Us

Address:

Building 4, Phase 2.5, Independent Entrepreneurship Park, Tianyi Science and Technology City, Tianyuan District, Zhuzhou City, Hunan Province, China

E-Mail:

chitanauto@163.com

Mr. Gong:

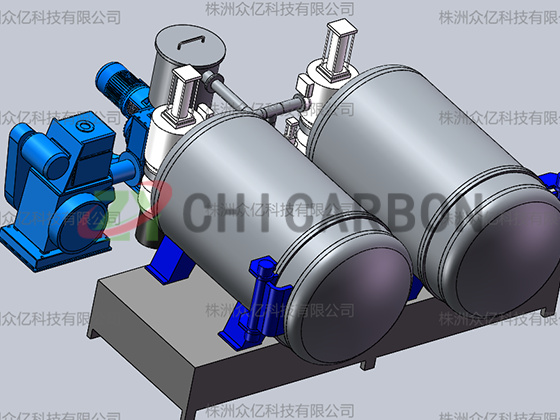

Silicon Oxide Vacuum Furnace

keyword:

Silicon Oxide Vacuum Furnace

Silicon Oxide Evaporation Furnace

Silicon Oxide Production Furnace

Silicon Oxide Vacuum Furnace

Product Description:

·Application: Suitable for vacuum deposition treatment of battery anode ‘Sio’ material.

Features:

·Silicon oxide (Sio) as lithium-ion battery anode material, abundant raw material reserves, low manufacturing cost, but the traditional silicon oxide vacuum furnace has problems such as blockage of the transition zone, air pressure in the collection area, and temperature in the collection area during the high temperature reaction/evaporation process, which can easily lead to the inability of the material to be effectively collected by high temperature reaction and the product qualification rate, which seriously affects the yield of SIO. The second-generation silicon oxide vacuum furnace produced and designed by our company well solve difficulties in the preparation process.

·High operating temperature, the highest operating temperature: 1500 ℃.

·The equipment adopts the optimised design of constant temperature field, graphite bar (plate) resistance or IGBT induction heating, the temperature field in the furnace is uniform.

·Equipped with programmable controller and human-machine interface, the whole process can be operated and monitored automatically, with full automation and manual mode.

·High safety, with PLC water, electricity, gas automatic control and protection, with over-temperature, water pressure, water flow, furnace body overpressure, water temperature and other protection.

Technical Parameters and Model Specifications:

·Configuration Specifications: horizontal or vertical

·Maximum operating Temperature: 1500℃.

·High-temperature Zone Volume Size: according to user requirements.

·Working Atmosphere in the Furnace: vacuum, nitrogen, argon.

·Temperature Uniformity: ≤ ± 5.

· Temperature Measurement Accuracy: 0.1%-0.5%

·Temperature Measurement Mode: tungsten rhenium thermocouple.

·Temperature Control: PID segmented programme control and manual control.

Product Specifications:

| Product Model Specification | ZY-YHG-450 | ZY-YHG-600 | ZY-YHG-W500 | ZY-YHG-W600 | ||

| Size and Volume (mm) | Φ450×H800 127L |

Φ600×H1300 367L |

500×500×1500 375L |

600×600×2000 720L |

||

| Rated Temperature (°C) | 1500 | 1500 | 1500 | 1500 | ||

| Limiting Temperature (°C) | 40 | 70 | 100 | 150 | ||

| Configuration Power (KW) | 40 | 80 | 150 | 200 | ||

| Temperature Difference in high Temperature Zone (℃) | ±5 | ±5 | ±5 | ±7 | ||

| Temperature Control Method | PID segmented programme control and manual control (Japanese conductive instruments) | |||||

| Heating Method | Graphite rod (plate) resistance or IGBT induction heating | |||||

| Operating Atmosphere | Vacuum, nitrogen, argon | |||||

| Ultimate Vacuum (pa) | 5 (empty furnace, cooling) (or customised according to customer requirements) | |||||

Product Showcase:

RELATED PRODUCTS

Graphite Carbonization Furnace

a kind of industrial heat treatment equipment specially used for the production of high performance carbon materials such as artificial graphite, anode materials, carbon/carbon composites and so on. It is used to carbonise carbon-containing precursors (e.g. petroleum coke, asphalt, resin, etc.) at high temperature (usually 1000°C~3000°C) in an inert atmosphere (e.g. nitrogen, argon) or in a vacuum environment, so as to form a high-purity graphite structure.

Heat Conducting Graphite Film Vacuum Carbonization Furnace

Mainly used for new silicon carbide material, carbon material, thermally conductive graphite film material pre-stage vacuum negative pressure decoking and medium temperature carbonization treatment.

1500℃ Silicon Oxide Vacuum Furnace

Suitable for vacuum deposition treatment of battery anode ‘Sio’ material

ONLINE CONSULTATION

Filling in your phone and email information will help us get in touch with you in a timely manner and resolve your issue as soon as possible.